We just moved Modular Robotics into a great new space in downtown Boulder, Colorado. If you’re local, come visit us at 2500 Pearl Street, right above Mike’s Camera. It’s no coincidence that our new building is in the shape of a cube. If you squint, you can see Mark through the window, and also the mad style of our old-doors-on-sawhorses work tables. And look – there’s UPS ready to bring our robots right to you.

I’m just now getting around to posting about the NSF SBIR Phase II Grantees meeting that I attended last month, in Baltimore. Our SBIR grant requires that we attend this meeting each year. The meeting is designed to help grantee businesses “share their technical and commercial achievements with the NSF program staff, potential investors and strategic partners, as well as having an opportunity to network with other small businesses for possible collaborations to grow their businesses.” Lots of information to help techies make their good ideas become reality.

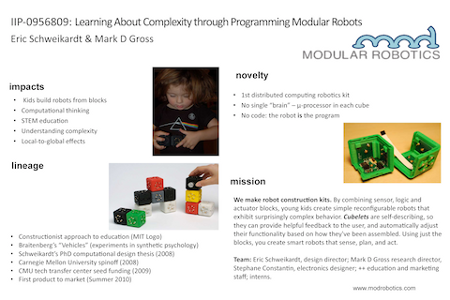

Of course, with hundreds of companies in a wide range of technical areas, the meeting can be overwhelming. For example, I went to a talk on “New Synthetic Approaches to Higher Performance, Lower Cost CO2/CH4 Gas Separation Membranes” — good stuff, but a little far from Modular Robotics’s core business. Still, it was good to meet the other SBIR II education grantees, which include our friends Alex Repenning (Agentsheets), Chris Hancock and Ricky Carter from Tertl Studios, and robotics company Road Narrows, Agile Mind (co-founded by Adele Goldberg), and many more. I don’t have any pictures from the meeting (big hotel ballroom with lots of people), but above you can see our dazzling entry for the poster session, where I also gave impromptu demos of our old prototype.

Hello! My name is Kelsey Metzler, and I’m a new design intern here at Modular Robotics. Over the last few weeks, I have had a lot of fun helping to set up the new Modular Robotics Studio Headquarters, learning all about the blocks, and contemplating how to build a 3D Printer (blog to follow soon!). Since I don’t get paid very much, I decided to take a play day. Today, I toyed around with Lego Mindstorms for the first time ever, and ended up learning a lot of really cool things!

Lego Mindstorms is a fun kit that enables kids (or, adults…) to make their own robots. The kit, like any Lego kit, has many different types of building blocks, connector pieces, gears, axles, unique building blocks… anything you need to build a sweet robot. This kit also has Lego servo motors, a light sensor, an ultrasonic distance sensor, a touch sensor, and a sound sensor. All of this paired with the NXT, or the ‘brain’ of the robot, gives you one awesome kit. The software behind Lego Mindstorms is made by National Instruments, the producer of the major software LabVIEW. The Mindstorms software beautifully resembles LabVIEW, a graphic based programming language. The software is intuitive and easy to use, especially for someone with experience in LabVIEW.

Today, I decided to see just what I could do with Lego Mindstorms. This is not only extremely fun, but is a great way to understand new mechanisms that might be used in future work. I started out by following some of the ‘Getting Started’ tasks that come with the Mindstorms software. These exercises are a great way to start getting to know Mindstorms. But, I wanted to do more! I started playing around with different ways of mounting sensors on the wheeled robot, logic for the robot involving case structures, and using many sensors at the same time.

The most exciting, albeit fairly simple robot that I built today has been named Sam. He drives towards something, and as he approaches it, slows down until he hits it. After he hits it, he quickly races backwards, turns a little bit, and drives forward again. An interesting challenge in building this robot was to make a bumper that actually senses bumping! Just a simple small button will only detect straight-on hits. After messing around with different types of bumpers for a little while, I decided to just do a distance sensor: when the robot gets really close to something, it backs up. It was very fun to watch the robot drive around running into things on the floor!

Then, I decided that I wanted to add clapping control. The goal was to have the robot pause for 2 seconds whenever I clap my hands. This didn’t turn out to be as easy as I had hoped! There are a few different ways I tried to do this: using a ‘switch’ block, using the ‘compare’ function, and using a ‘logic’ function. The thing that I found the most difficult about working with Mindstorms software is how very simple it is. I am used to working with LabVIEW, in which there are thousands of functional blocks to choose from. In Mindstorms software, there are less than 25. I discovered a ‘custom’ block option today, however… so it might be possible to make many more complex blocks to work with. In any event, I have not yet found a way to actually get the clapping control functional! At this point I just have a robot running around, charging into things and then backing up and doing it again.

Wednesday entertainment: Sam.

We’re pleased to announce the award of a two-year $486,906 grant from the US National Science Foundation’s Small Business Innovative Research (SBIR Phase II) program. The grant project is called “Learning About Complexity through Programming Modular Robots” and it’s for our work developing a system through which kids interact with our modular robot kits. You can read the abstract at the NSF or take a look at our formal press release.

One great thing about this grant is that it will let us speed up. Until now, we’ve been running Modular Robotics on a very tight budget with a very small team. Our prototypes are still assembled in Eric’s garage. The SBIR funding will allow us to hire three more people, move into a “real” studio, and make many more robots much more quickly.

Another great thing is that it will let us slow down. Like any small business, we’ve been a little harried recently. We’ve been trying to get our robot kit out the door as quickly as possible before we run out of money. It’s expensive to make lots of tiny robots, so we’ve been making a lot of compromises in our rush to get something available. Although we’re still going to have a first round of robot kits available this summer, the grant funding allows us to pay attention to the fine details of the design and make sure we’re releasing our robots thoughtfully and deliberately.

Anyway, we’re thrilled. Coming soon: thousands and thousands of tiny robots.

Since we’re getting close to firing up the injection molder for our first run of commercial blocks, we’ve been thinking a lot about color. We use color to differentiate the different blocks by function, and we want the colors to both make sense and look cool when the blocks are assembled into a robot. In our research prototypes we made Action blocks white, Sense blocks black, and used rainbow colors for the rest. The rainbow just happened because of the material colors that were available for the Stratasys 3D printer we were using — it seemed a little too young, like how the color and scale of Duplo makes it obvious that it’s for little kids. And the white got dirty easily.

For our first run, Sense blocks will still be black, but Action blocks will be transparent. The transparent cubes look great (they remind me of Capsela) and we’ll be posting some new photos shortly. And we’re settling on the color palette shown above for the Think and Utility blocks. It’s not a rainbow but the colors are easy to differentiate. It’s a little earthy, and since Passive blocks will be green, may even make a robot look a little bit natural.

One big influence on our Modular Robotics concept is the book, Vehicles, by Valentino Braitenberg. If you don’t already know this book, you’re in for a treat! In short and simple chapters, Braitenberg leads the reader through a series of thought-experiments in synthetic psychology. The ‘vehicles’ are creatures made of motors, sensors, and simple neuron-like logic gates. The first vehicles, for example, move toward or away from light. Gradually, as you connect the sensors, motors, and logic in more complex ways, the vehicles begin to seem to exhibit lifelike behaviors.

How many Vehicles will we be able to make with our robotics construction kits?

We’ve been awfully excited to use 100% recycled plastic for the shells of our robotic construction kit. We were going to end up using two materials for the blocks: black recycled ABS and clear recycled PET (from soda bottles). Using materials that have already been around the block and into the bin made us feel better about our contribution to the mountain of stuff around us. And that’s why it’s pretty upsetting to find out that we probably cannot use recycled plastic at all.

In 2008, the Consumer Product Safety Improvement Act (CPSIA) was signed into law in the US. Don’t get us wrong, the law is a good thing: it protects kids from lead and other harmful substances in toys, and requires mandatory third party testing for all children’s products. One important group of substances regulated by the new law is phthalates, which are chemicals added to plastic during manufacturing to make them more flexible and durable. Heavy exposure to phthalates, unfortunately, has been shown to cause endocrine disruption and infertility.

To comply with the CPSIA, our plastic must meet a certain requirement for phthalate levels. But since recycled plastics are just a mix of old plastics ground up and reheated, no supplier will guarantee that every part will meet the requirements. So while we haven’t given up on our search for a better option, unfortunately it looks like our only option is to use virgin plastic. Any thoughts?

A tip of the hat to Pittsburgh’s Kids & Creativity group – a loosely linked collection of artists, media folk, museum directors, hackers, teachers, professors, businesses, philanthropists, all working to make the Pittsburgh region an amazing place to be a kid. And because Pittsburgh is a center for both technology and the arts, many of the projects work at this intersection. The group — now about a hundred strong — meets monthly for a vibrant exchange of information and ideas, and yesterday’s meeting at the Carnegie Science Center was a flood of conference and meeting reports, from the Game Developers to Interaction Design for Children to SIGGRAPH. I’m relatively new to Pittsburgh (5 years now) and through Kids and Creativity I get to hang out with the most amazing and committed and imaginative people. Kudos to Gregg Behr, executive director of the Grable Foundation, who seems to know everyone and has that special knack to bring very disparate worlds together.

Educational robotics is a mess. There are a bunch of different platforms, and teaching materials can be ad-hoc. The contests have been successful but the First people don’t talk to the Botball people. That’s why we’re pleased that iRobot has started putting together SPARK, an educational resource site for teachers and students. They’re collecting information and activities and trying to start a lively educational robotics community.

It’s nice to see Modular Robotics listed up there next to heavyweights like LEGO and VEX. Thanks, iRobot, for developing an inclusive community site dedicated to improving educational robotics.

3D printers are amazing tools: design an object on your computer, hit control-P, and when you come back from lunch, a nice warm plastic part is waiting for you. For a few years now, I’ve been making prototype plastic parts on a trusty Stratasys Dimension. It’s quick and makes robust ABS parts at the touch of a button: I just draw in Solidworks and usually have a finished part the next day. But at the scale of parts for the robotic construction kit that we’re working on, we’ve run up against a resolution wall. The Dimension, with a resolution of about 178 microns, just can’t print print the fine details I need at this stage of design.

Enter the Objet Eden. It’s different technology; the material is deposited by a bunch of print heads in parallel, much more like an inkjet printer than the “hot glue gun on a robot” style of FDM. And the parts are beautiful. Layers are only 16 microns (16 microns!) thick, so parts are smooth to the touch, even shiny, when they come out. The picture above is a test print of a 40mm cube, and it’s perfectly smooth; no ridges or bumps. It’s fast, too — these parts printed in 80 minutes. The material seems strong and durable, and the support material washes off with water. The only catch is that the machine costs about $115,000.