We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

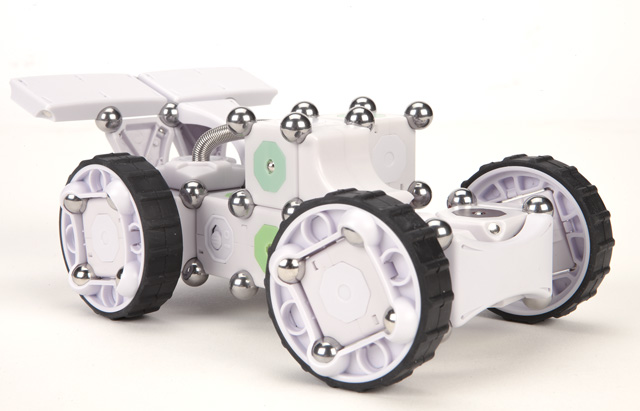

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

Chocolate Santa (an affectionate nickname for Tony, our UPS guy) just picked up the first 40 MOSS kits from our little factory at Modular Robotics. They’re headed out to our first 40 Kickstarter backers and thus, today marks an exciting milestone. After almost three years in development, we’re shipping the MOSS Robot Construction System! And it’s awesome.

Did you pledge on Kickstarter or pre-order for a MOSS Basic Builder Kit? Ho, ho! I have some good news for you. We decided to upgrade all Basic Builder Kits to the Zombonitron 1600 Kit. Extra parts! In addition to everything that was in the Basic Builder, you’ll get a Brightness Sensor, an extra Corner Block, two extra Double Spans, and 26 more Steel Spheres. In the months between the Kickstarter campaign and now, we’ve been building thousands of MOSS robots, and it turns out that these extra parts really expand the universe of robots that you can build with this kit.

We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

We had estimated that we’d be able to ship in February, and we’re finally opening the MOSS pipeline in the last days of March. If our delay screwed with your kid’s birthday or was annoying in another way, please accept my apology: I’m sorry we were late!

Honestly though, I’m blown away by how quickly and efficiently team Modbot moved to get MOSS from prototype to product. MOSS has hundreds of parts in it, most are completely custom, and we’re assembling and testing everything in our own shop in Boulder, CO. The complexity of this effort is astounding and I find myself extremely impressed that we’re shipping only a month or two late. Cubelets took a year longer than planned and every other physical gadget I’ve supported on Kickstarter has shipped with a far longer delay than MOSS.

Last week I ended up in Valdez, Alaska. It just happens to be the 25th anniversary of the oil spill, which I remember vividly watching and reacting to as a twelve year old. That event did a lot to shape the way that I think about the world, but that’s another story. Valdez is the end of the Trans Alaska pipeline, and seeing all of that infrastructure made me think a little bit about the Modular Robotics production pipeline that creates tiny robots and sends them out into the world. Over the last month we’ve been able to assemble some MOSS modules but we’ve been waiting on parts to assemble others. That creates a sort of MOSS reservoir at the beginning of the pipeline. In the last week, as we’ve finally been able to build the few remaining modules in the Zombonitron 1600 kit, we’ve been able to open the valve and start shipping. Right now it feels like we’re running only a trickle of water through our pipeline because we’re triple-testing everything and improving processes as we go. But we’ve designed our pipeline to hold thousands and thousands of tiny robots at a time, so it’ll be fun to watch the volume increase over the next few months.

Kickstarter backers and pre-order friends, we’re amped to send out MOSS to you soon. We don’t have an exact schedule of who gets what when yet, but as our pipeline stabilizes a bit and we have enough data to project, we’ll post better delivery estimates here. For everyone else, we’ll have MOSS available on our web site as soon as we get the pre-orders out the door! In the meantime, here are a few MOSS robots to tide you over.

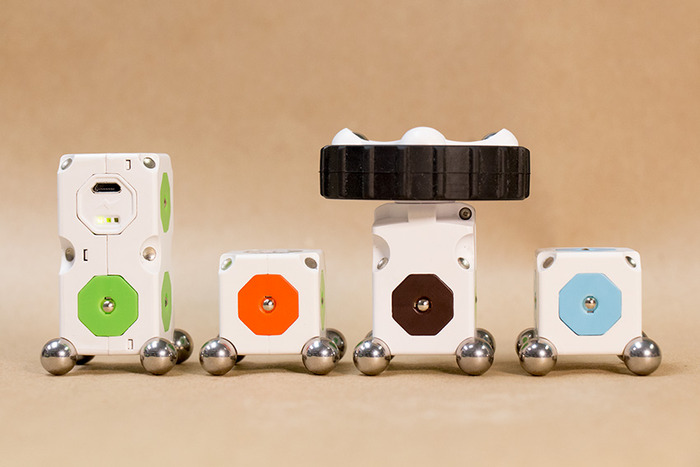

Colors are locked, and they’re gorgeous. The photo below is a little wonky and still doesn’t show the colors accurately, but we just shot beautiful new pro photos and I’ll post them asap. We vacillated a lot with color selection, made a last-hour decision to switch to a two-color face scheme, and then reversed that in a last-minute decision to in favor of the original four-color face scheme:

Colors are locked, and they’re gorgeous. The photo below is a little wonky and still doesn’t show the colors accurately, but we just shot beautiful new pro photos and I’ll post them asap. We vacillated a lot with color selection, made a last-hour decision to switch to a two-color face scheme, and then reversed that in a last-minute decision to in favor of the original four-color face scheme:

We’re still on track to get the first MOSS kits out the door in February!

We’re still on track to get the first MOSS kits out the door in February!