I’ve been having a lot of fun at Modular Robotics lately. It’s been a bit of a whirlwind with a lot of changes, a lot of new collaborators, a lot of new ideas, and a lot of creative problem solving. It never occurred to me that we’d grow by acquiring other companies, but here we are: just a few weeks ago, we completed the transaction to merge with

Dexter Industries and we’ve been busy integrating our new team members and making plans for the future.

Dexter has been on my radar since about 2013. Back then, they were making a bunch of interesting high-end sensors and extensions for LEGO Mindstorms, and I thought the idea was compelling: build on a commercially successful construction kit to enable kids (and

AFOL) to explore further than the stock pieces and configuration allowed. Dexter has grown and changed quite a bit since then, focusing over the last few years on mobile robots for education. They’re still building off of the work of other successful projects; the

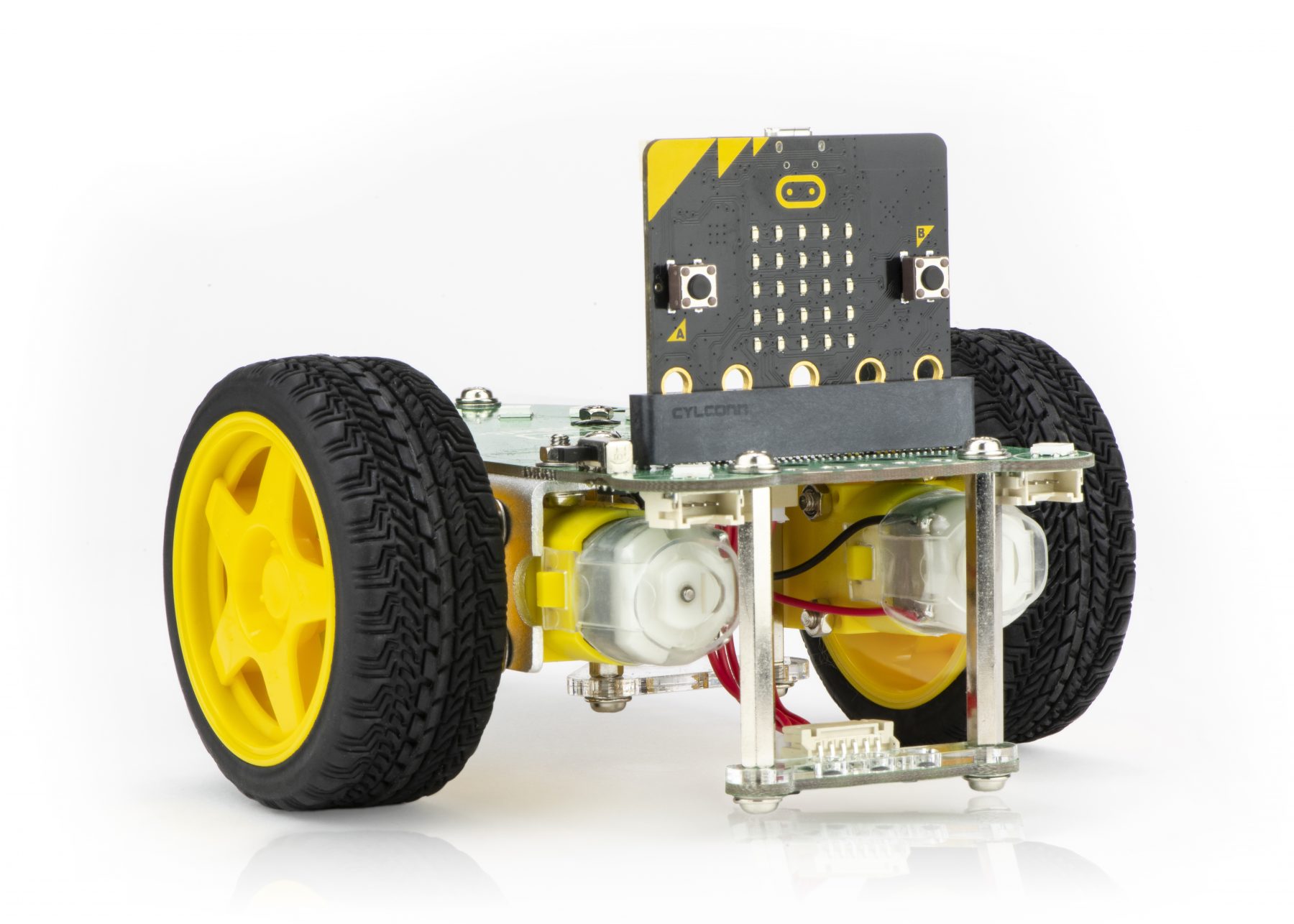

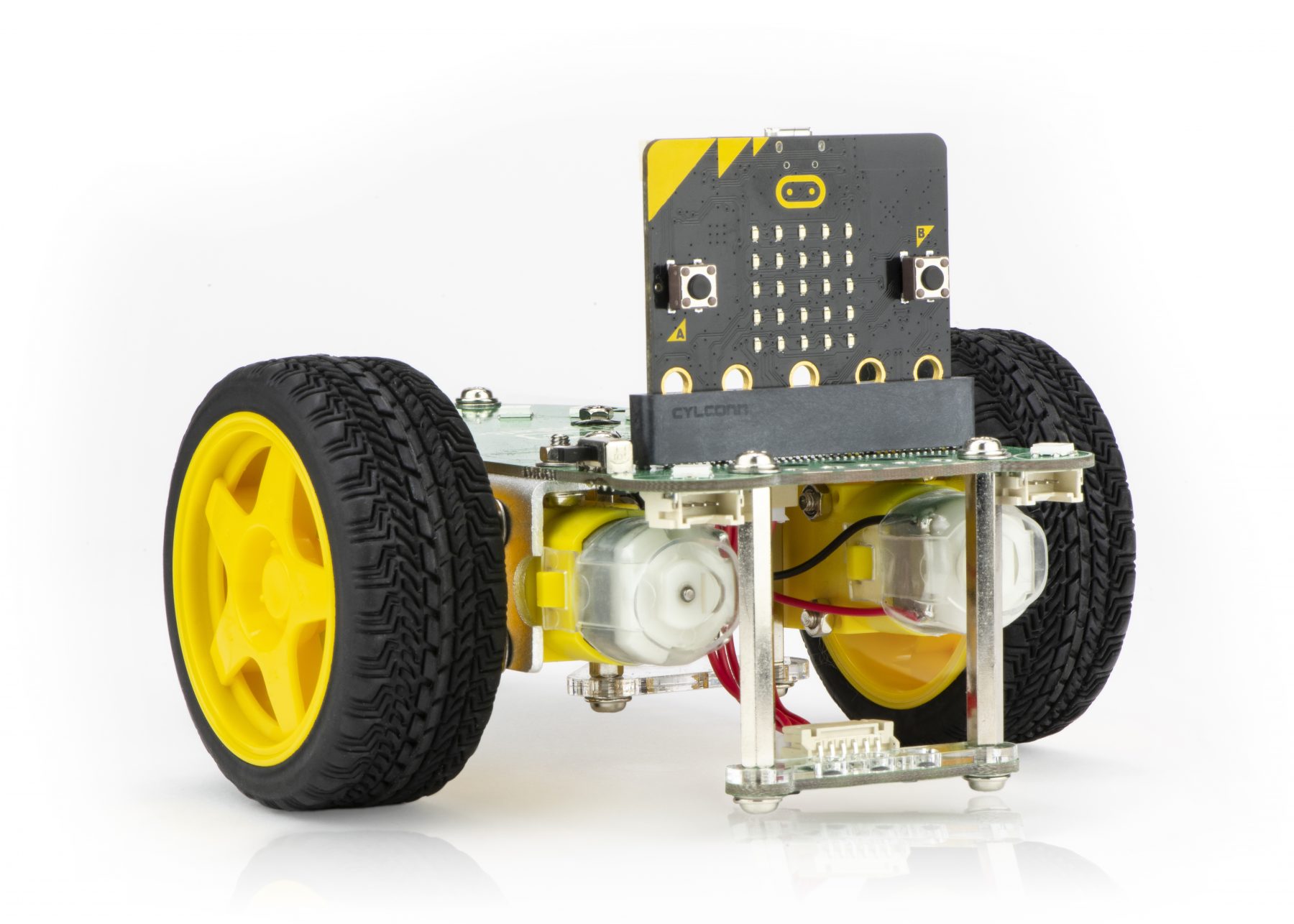

Gigglebot, below, is built around a

micro:bit and the

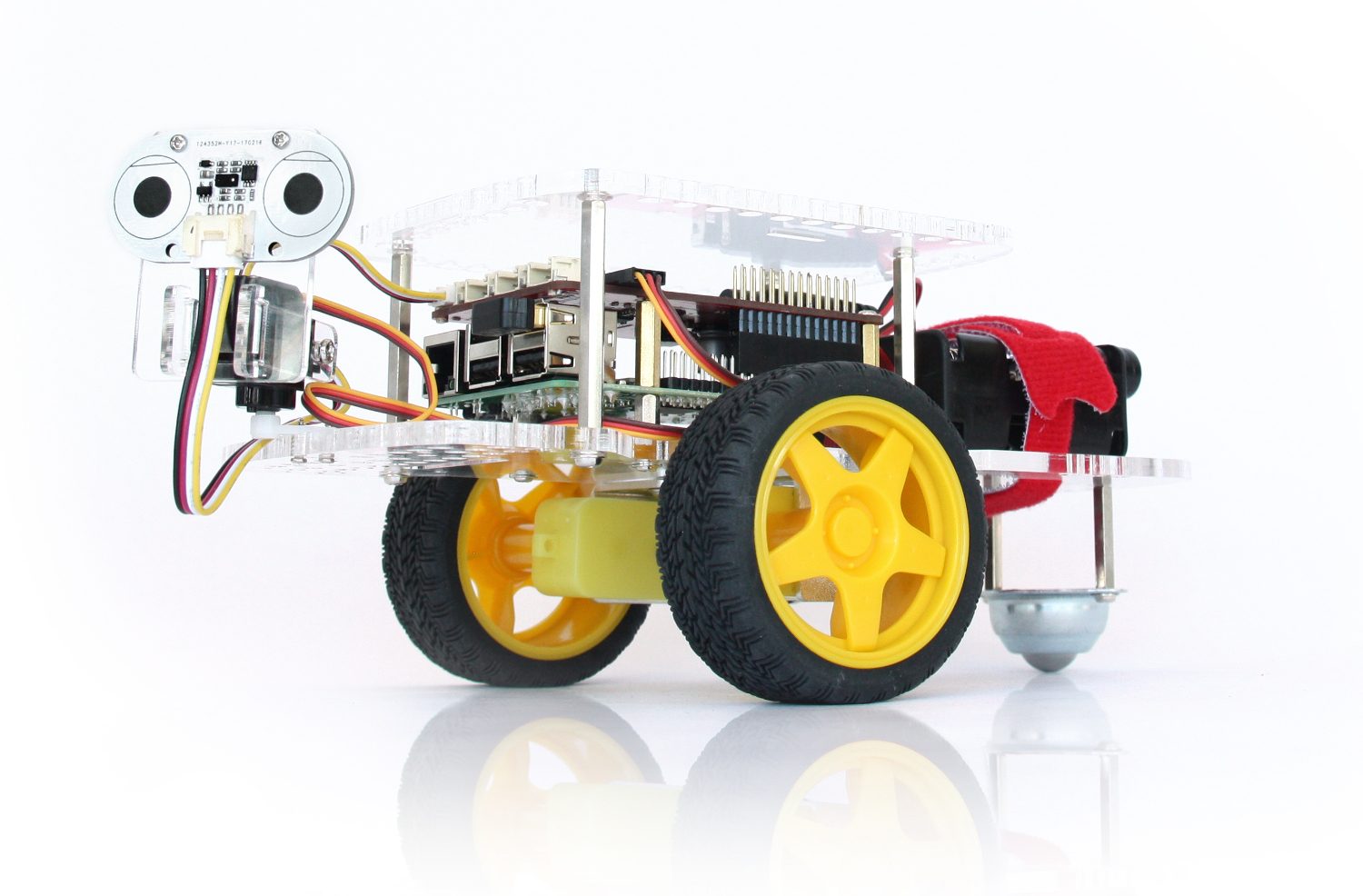

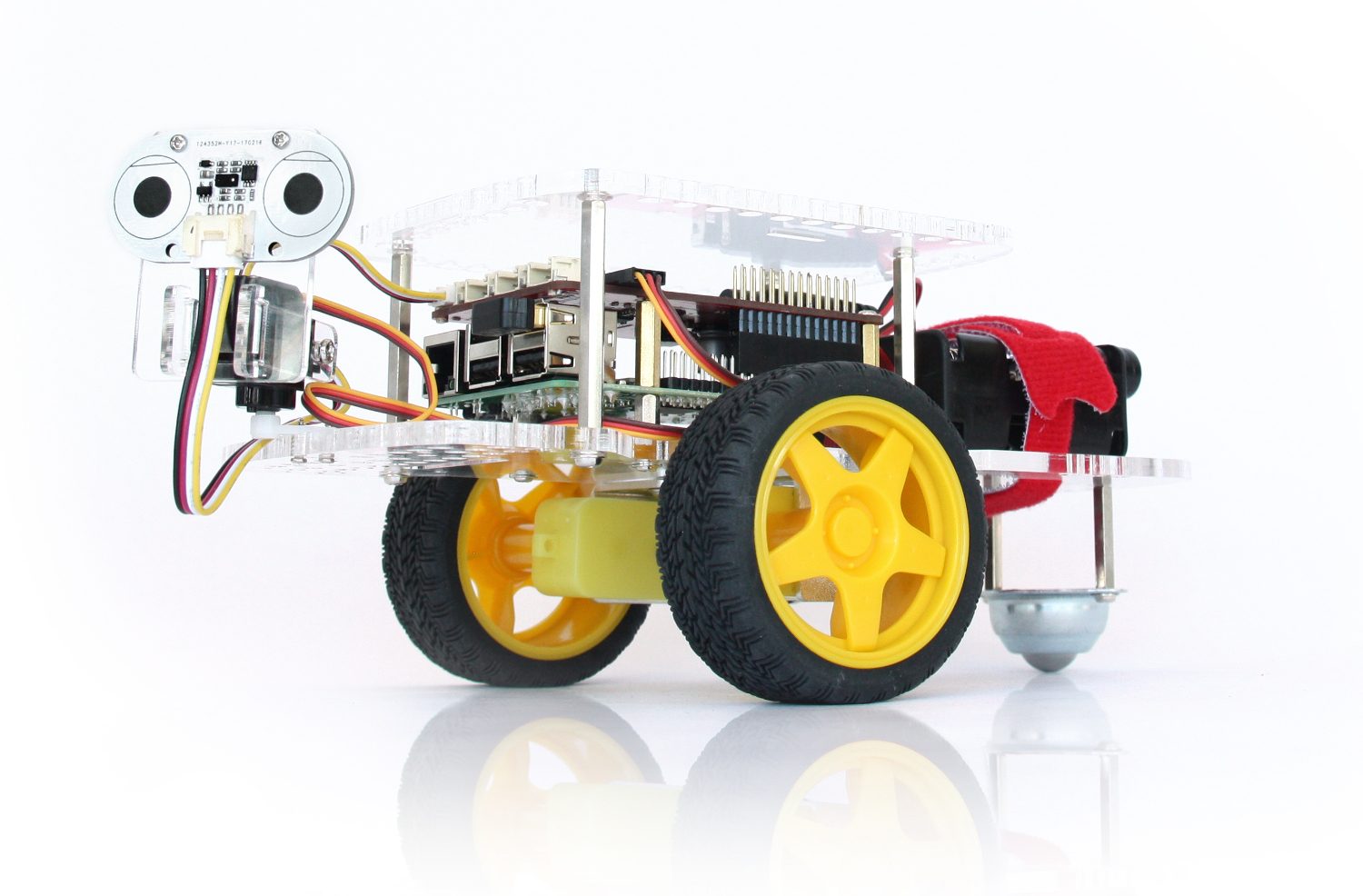

GoPiGo, further down, is built around a

Raspberry Pi.

Up until a couple of years ago, we didn’t think much about teaching kids to code. I feel strongly that the push to teach coding in elementary schools is misguided: that we should start with teaching computational thinking, away from a computer screen, and only get kids started coding when it starts to become something that they want or need to do in order to solve a problem or make something. We hear all the time about how it’s important to teach little kids to code, but most of the time I think we’re hearing it from people who don’t really code themselves and see it naively as a step on the path to a good twenty-first century job. Those of us who write code every day know that it’s just one of many tools needed to design something. It’s important to start from the beginning, with logic, computational thinking, and creativity, before moving to programming.

I’m proud that Cubelets have been a big success at helping kids learn to think. With Cubelets, kids as young as four are learning about things like feedback, control, loops, recursion, inputs/outputs, sensors, and networking all before they start programming. Later, after kids learn the basics of programming, Cubelets are again a powerful tool: kids can code them to make complex distributed systems: concurrent models of cities, animals, and ecosystems. But the complexity of Cubelets makes them not the best tool for the step in the middle: learning and practicing the basics of programming. Since Cubelets are a parallel system, they can quickly get complicated for learning to code. It’s much easier to start small and code a simple robot than it is to code an interconnected mass of twenty!

I first learned some programming in

Logo. My dad tells the story of coming to first grade parents’ night at Coleytown Elementary School in 1983 or so and seeing me demonstrate directing my little green turtle icon around on an Apple II screen with lines of code. My dad likes to say that he saw the future that night. He went home and bought a Commodore 64, learned how to use it, and later, as a professional photographer, became an early adopter of digital imaging, Photoshop and image databases. Anyway. Something about using code to create geometric patterns and illustrations was the bait that drew me in.

A lot of people don’t know that

the first Logo turtles were physical robots, not the familiar on-screen triangles. Back in 1960 it wasn’t practical to have a physical robot for every kid, so we made do with on-screen simulations. In 2019, it’s eminently practical, and the real-world behavior, tangibility, physicality, and connection to natural systems make robots an excellent tool for teaching kids to code.

At first, we thought we’d design a coding robot from scratch. Modular Robotics is a spinoff from an academic research lab at Carnegie Mellon University, and the desire to invent new things is part of our culture. But after a few discussions with John Cole, Dexter’s founder and CEO, it was apparent that there was a better path right in front of us. On July 1, 2019, Modular Robotics bought Dexter Industries, and not only have we expanded the set of learn-to-code tools in our product line, we’ve got a great new team of experts to work with moving forward.

John is a pretty amazing human being. He started Dexter Industries in his kitchen, after working in alternative energy and a variety of other fields too. He has an insatiable curiosity, combined with the capability to realize his crazy ideas, and that draws everyone toward wanting to work with him. Over the last ten years he’s spent time in Afghanistan, India, Iraq, and many other places, and has some unique stories to tell. I’m honored and thrilled to have him on the Modular Robotics team as a close collaborator, along with the impressive collection of characters who make up the rest of the Dexter team.

People seem to recoil a bit at the word “synergy”. I think it gets thrown around too much in the business community and has lost some of its meaning. But in the context of mergers and acquisitions, it has a very specific meaning. Putting our two companies together results in a lot of synergies; areas in which the best of one company can combine with the best of the other, creating a whole that’s more than the sum of its parts: a whole that’s more like the product of its parts. By multiplying Modular Robotics’ operations, reach, design, education experience, and network with Dexter’s innovation, engineering, university programs, and coding robots, we’re way more effective than when both of us were out there trying to do everything on our own. If you still hate the word “synergy,” maybe try

syzygy. It’s a much cooler word. Or

zymurgy, which I fondly recall from being a little kid who read the dictionary, often backward. Ok, sorry, I’m getting distracted.

We’re making one awesome change immediately. Starting today, all of the Dexter curricula, lesson plans, and activities will be available free of charge, under a Creative Commons license, for educators to download, remix, and re-use, however they desire. It’s a treasure trove of awesome content and I’m psyched to get it into more teachers’ hands. The materials that the Dexter team have designed and built over the years are a direct fit with our mission, and making them available at no charge feels like a great way to quickly scale up and help many more kids become better thinkers.

Other changes will be slower. We’ve already got our design, education, and engineering teams collaborating on a couple of new Cubelets and some educational material to be launched early next year. We’re starting in on a couple of top secret projects as well. For now, the Gigglebot, GoPiGo, BrickPi, GrovePi, and the rest of the new products will stay branded as Dexter Industries products. When you place an order, it’ll ship from Modular Robotics in Boulder, Colorado, and when you email customer support, you’ll be reaching our new, combined team. I’m excited to share some fun new things in the coming months, but for now, we’re charging ahead and trying to break as few things as we can in the meantime.

Zooming back out for a minute, I’m tremendously proud that our team was able to put this merger together, especially within the current context of quite a few IoT and consumer robotics companies (

Anki,

Jibo,

Reach…) shutting down. Casual observers might make an assumption that the consumer robotics market isn’t as promising as previously thought, but I’m certain that’s incorrect and that all of those companies were simply spending way more money than they were making.

Hardware is hard, no doubt, but as we get closer to shipping the millionth Cubelet, it feels like we’ve built a strong foundation helping kids become better thinkers. This acquisition allows us to immediately scale up and impact a greater number of kids and a more diverse set of learners. I’m incredibly excited for what’s next.

The Dexter Industries Rechargeable Battery Packs have the potential to short circuit, causing them to overheat and posing a potential burn hazard. While there have only been a few instances of this issue, we want to make sure your homes and classrooms are safe even if your robots are in storage.

We recommend that you immediately cease using the Dexter Industries Rechargeable Battery Packs, and have a professional safely dispose of them according to local laws. If you need help finding a disposal site, please click this link, ensure the battery type selected is “Nickel-metal Hydride” and enter your zip code to locate one near you.

Modular Robotics is offering a free replacement battery pack to all affected by the recall. To sign up, visit the official battery recall site or contact our toll-free 24-hour hotline at 877-233-6859.

In the meantime, GoPiGo and BrickPi robots are perfectly safe to use with traditional AA batteries (standard or rechargeable).

The Dexter Industries Rechargeable Battery Packs have the potential to short circuit, causing them to overheat and posing a potential burn hazard. While there have only been a few instances of this issue, we want to make sure your homes and classrooms are safe even if your robots are in storage.

We recommend that you immediately cease using the Dexter Industries Rechargeable Battery Packs, and have a professional safely dispose of them according to local laws. If you need help finding a disposal site, please click this link, ensure the battery type selected is “Nickel-metal Hydride” and enter your zip code to locate one near you.

Modular Robotics is offering a free replacement battery pack to all affected by the recall. To sign up, visit the official battery recall site or contact our toll-free 24-hour hotline at 877-233-6859.

In the meantime, GoPiGo and BrickPi robots are perfectly safe to use with traditional AA batteries (standard or rechargeable).

Once again, if you have a Dexter Industries Rechargeable Battery Pack, please register at the official battery recall site or contact 877-233-6859. You will automatically be eligible to receive a replacement battery pack after registering.

This recall only pertains to the Rechargeable Battery Pack sold with the GoPiGo and BrickPi robots, and does not affect any other Dexter robots or Cubelets robot blocks.

Once again, if you have a Dexter Industries Rechargeable Battery Pack, please register at the official battery recall site or contact 877-233-6859. You will automatically be eligible to receive a replacement battery pack after registering.

This recall only pertains to the Rechargeable Battery Pack sold with the GoPiGo and BrickPi robots, and does not affect any other Dexter robots or Cubelets robot blocks.

Up until a couple of years ago, we didn’t think much about teaching kids to code. I feel strongly that the push to teach coding in elementary schools is misguided: that we should start with teaching computational thinking, away from a computer screen, and only get kids started coding when it starts to become something that they want or need to do in order to solve a problem or make something. We hear all the time about how it’s important to teach little kids to code, but most of the time I think we’re hearing it from people who don’t really code themselves and see it naively as a step on the path to a good twenty-first century job. Those of us who write code every day know that it’s just one of many tools needed to design something. It’s important to start from the beginning, with logic, computational thinking, and creativity, before moving to programming.

I’m proud that Cubelets have been a big success at helping kids learn to think. With Cubelets, kids as young as four are learning about things like feedback, control, loops, recursion, inputs/outputs, sensors, and networking all before they start programming. Later, after kids learn the basics of programming, Cubelets are again a powerful tool: kids can code them to make complex distributed systems: concurrent models of cities, animals, and ecosystems. But the complexity of Cubelets makes them not the best tool for the step in the middle: learning and practicing the basics of programming. Since Cubelets are a parallel system, they can quickly get complicated for learning to code. It’s much easier to start small and code a simple robot than it is to code an interconnected mass of twenty!

I first learned some programming in

Up until a couple of years ago, we didn’t think much about teaching kids to code. I feel strongly that the push to teach coding in elementary schools is misguided: that we should start with teaching computational thinking, away from a computer screen, and only get kids started coding when it starts to become something that they want or need to do in order to solve a problem or make something. We hear all the time about how it’s important to teach little kids to code, but most of the time I think we’re hearing it from people who don’t really code themselves and see it naively as a step on the path to a good twenty-first century job. Those of us who write code every day know that it’s just one of many tools needed to design something. It’s important to start from the beginning, with logic, computational thinking, and creativity, before moving to programming.

I’m proud that Cubelets have been a big success at helping kids learn to think. With Cubelets, kids as young as four are learning about things like feedback, control, loops, recursion, inputs/outputs, sensors, and networking all before they start programming. Later, after kids learn the basics of programming, Cubelets are again a powerful tool: kids can code them to make complex distributed systems: concurrent models of cities, animals, and ecosystems. But the complexity of Cubelets makes them not the best tool for the step in the middle: learning and practicing the basics of programming. Since Cubelets are a parallel system, they can quickly get complicated for learning to code. It’s much easier to start small and code a simple robot than it is to code an interconnected mass of twenty!

I first learned some programming in  People seem to recoil a bit at the word “synergy”. I think it gets thrown around too much in the business community and has lost some of its meaning. But in the context of mergers and acquisitions, it has a very specific meaning. Putting our two companies together results in a lot of synergies; areas in which the best of one company can combine with the best of the other, creating a whole that’s more than the sum of its parts: a whole that’s more like the product of its parts. By multiplying Modular Robotics’ operations, reach, design, education experience, and network with Dexter’s innovation, engineering, university programs, and coding robots, we’re way more effective than when both of us were out there trying to do everything on our own. If you still hate the word “synergy,” maybe try

People seem to recoil a bit at the word “synergy”. I think it gets thrown around too much in the business community and has lost some of its meaning. But in the context of mergers and acquisitions, it has a very specific meaning. Putting our two companies together results in a lot of synergies; areas in which the best of one company can combine with the best of the other, creating a whole that’s more than the sum of its parts: a whole that’s more like the product of its parts. By multiplying Modular Robotics’ operations, reach, design, education experience, and network with Dexter’s innovation, engineering, university programs, and coding robots, we’re way more effective than when both of us were out there trying to do everything on our own. If you still hate the word “synergy,” maybe try